The ability to convert or exchange complete levels during operation increases the variability of the configuration and the flexibility of the process. Our design also allows short-notice changes in the just-in-time process.

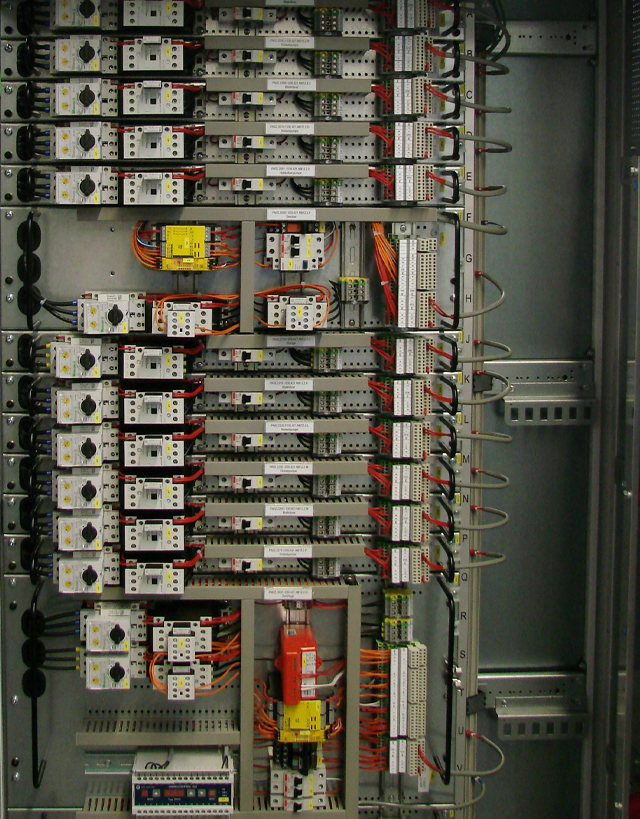

The modular design of the contacts and the division into three adapter sizes, means drawers can be built up to a load of 630 A. In addition, there are 20 control contacts and 10 contacts for control voltages available, regardless of the slot size.

All adapters – the connections between insertion unit and field rails or cable compartment – are ready for operation and tested units are simply mounted at the desired location.

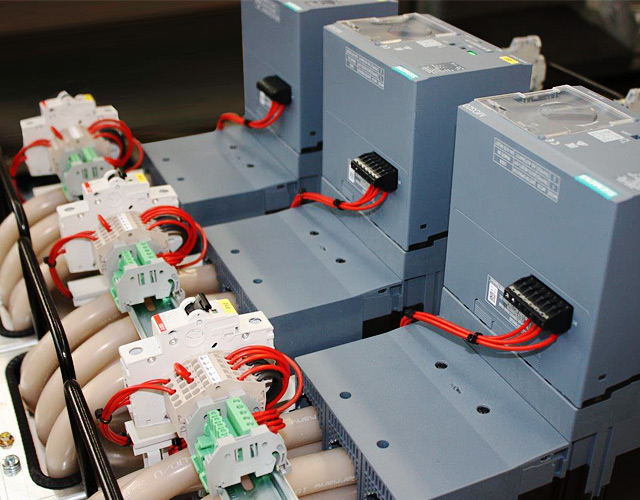

Plug-in technology allows for the rapid exchange of data between the system and higher level automation.